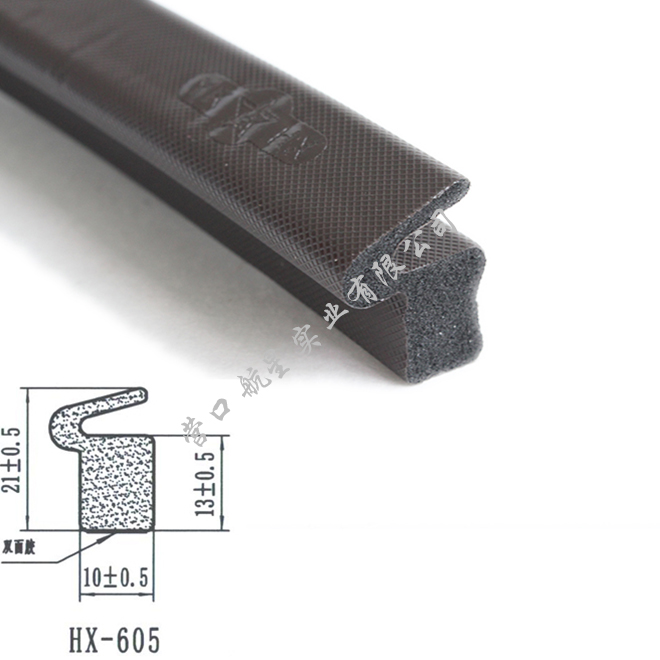

Can be divided into solid core products (round, square, flat cross-sectional shape), hollow products and metal rubber composite products and other types. Among them, metal rubber composite seals account for more than 60%. Cross section design is critical for rubber seals. The first is the shape and size of the sealing lip, and the sealing lips on both sides should contact the glass from both sides of the window glass with the same force of the appropriate size. The length and thickness of the lip should be appropriate. Too thick and too long will increase the resistance of the glass. Too thin or too short will lead to poor guidance and sealing of the glass, resulting in vibration, noise, and leakage of the rain. The shape and size of the bottom of the section are designed. There are protrusions on the steel channel section of the window. The function is to assemble the guide groove. Therefore, the bottom of the guide groove section should be designed with a corresponding structure, which is easy to install and can use the elasticity of the sealing strip itself. Adhere to the steel guide groove to prevent it from coming out; Finally, the outer edge of the shape, size, in order to improve the appearance of the guide groove outside the surface should be closely with the body.