At present, the traditional sealing strips on the market are made of rubber material. This kind of material is prone to ageing and has poor elasticity. It is particularly constrained by the ambient temperature, and some rubber sealing strips have a sharp drop in elasticity when they encounter low temperatures. High-temperature oxidation releases substances harmful to the human body (such as CO, SO2), odors, and poor sealing performance. It has gradually been replaced by this new type of encapsulated seal.

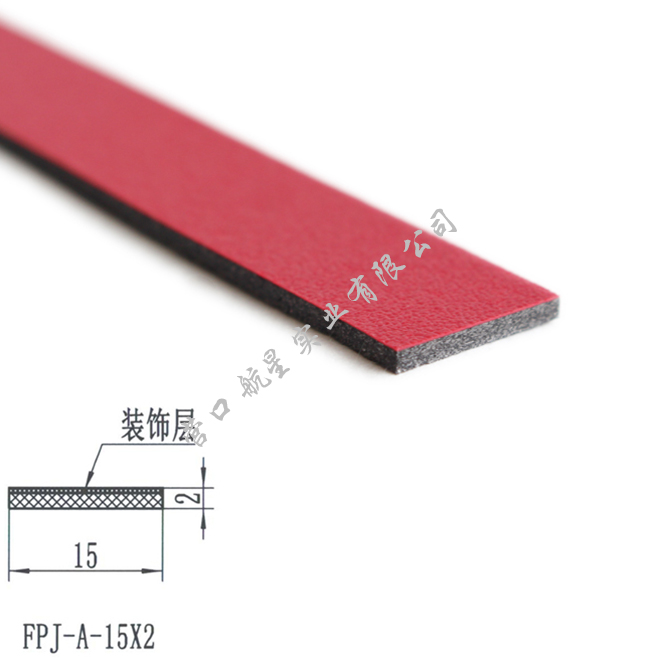

The new generation of cover seals consists of high-rebound PU foam, outer PE film, and inner pp (polypropylene) support skeleton. High-resilience PU foam has high resilience , Below 10% compression deformation, can effectively guarantee the long-term sealing of doors and windows; outer PE film can greatly extend the life of the product, rich colors, making the appearance of gorgeous novel; PP support skeleton to play a fixed installation product Effectively prevent product shrinkage. The utility model has the following advantages: non-toxic environmental protection, noise reduction and noise reduction, 20 years of long service life, heat preservation and energy conservation, an ultra-wide environmental use range of -40°C to 90°C, passing 500,000 fatigue tests, and excellent physical properties of the product. In the long-term use, maintain the sealing performance of doors and windows.